Screw Conveyors

Screw conveyors are often used inside plants because they are completely enclosed, thus material transfer is weather-proof and dust-free. Thanks to the small number of installed components, these machines require minimum maintenance.

Screw conveyors are often used inside plants because they are completely enclosed, thus material transfer is weather-proof and dust-free. Thanks to the small number of installed components, these machines require minimum maintenance.

They are often used inside plants because, being completely closed, they allow for a transport without the emission of dust; moreover, thanks to the limited number of components installed, these machines require minimal maintenance.

Motridal’s range of production varies from the most common tubular or channel trough screw conveyors, to screw feeders, dozers, and mixers, where process and transport requirements are combined. Trough ends are dust-tight with bearings suitable both for radial and axial loads; longer screw conveyors are equipped with intermediate hanger bearings, in order to minimise shaft deflection. Thanks to its Augers Division, that produces forged and continuous flighting, Motridal can manufacture, upon request, machines for special purposes, with shape, dimension and materials, not included in standard production.

Motridal supplies tubular and troughed screw conveyors suitable for all industrial sectors. Depending on the application and specific requirements, the built materials are appropriately selected (carbon steel, stainless steel, anti-wear steel, alloys resistant to high and low temperatures).

Hot materials, like ashes, are often required to be cooled down before discharging or conveying to downstream process. Motridal, if the process conditions allow it, is able to design and provide water cooled screw conveyors to reach the desired outlet material temperature.

I trasportatori a coclea sono utilizzati in alcuni processi per miscelare tra loro prodotti differenti durante la fase di trasporto. Numerose soluzioni di progetto e configurazioni sono disponibili per soddisfare le esigenze di ogni specifica applicazione.

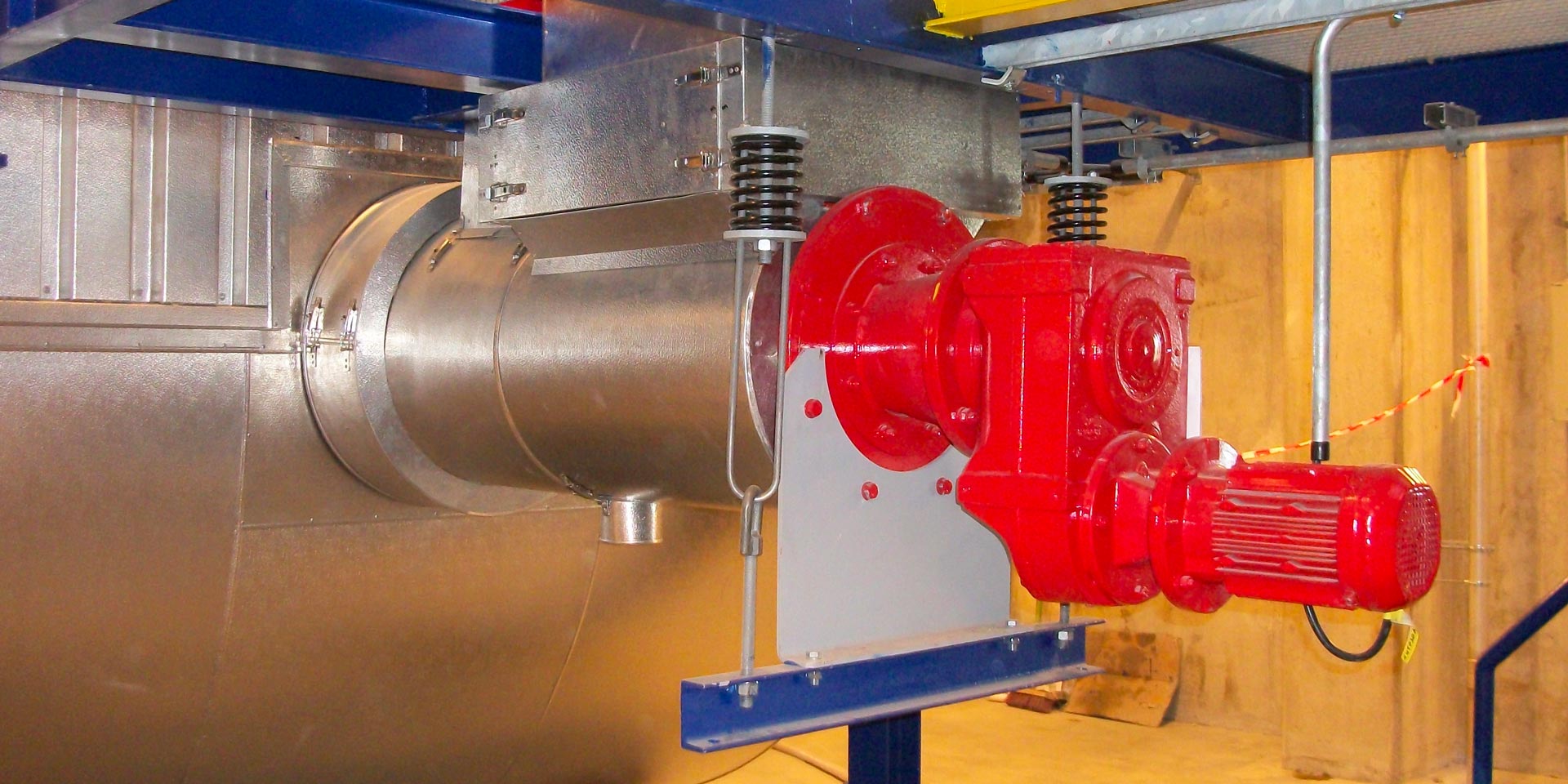

Motridal includes in its production range injection screw conveyors, designed to channel the material directly into tanks, boilers and furnaces. The casing is provided with a flanged front-end discharge, while the drive head is fitted with a coupling lantern to support the screw shaft in a cantilever configuration.

In case of very fine products, like cement and ashes, vertical screw conveyors are a valid alternative to bucket elevators for lifting the material. Motridal design and manufactures vertical screw conveyors up to 20m height and 500 TPH.

Screw conveyors are one of the preferred equipment to restore or increase the moisture content in the bulk material. Proper spray nozzles design together with the mixing capacity of this type of conveyor make this operation easily achievable. Furthermore the dust tight design and construction material selection make the process safe and durable.

The transport of sticky materials, like muds, requires a self-cleaning solution as the shaftless screw conveyors. A continuous flight directly supported by the casing is the common application. Motridal is able to provide this type of conveyor with any size and length technically feasible.

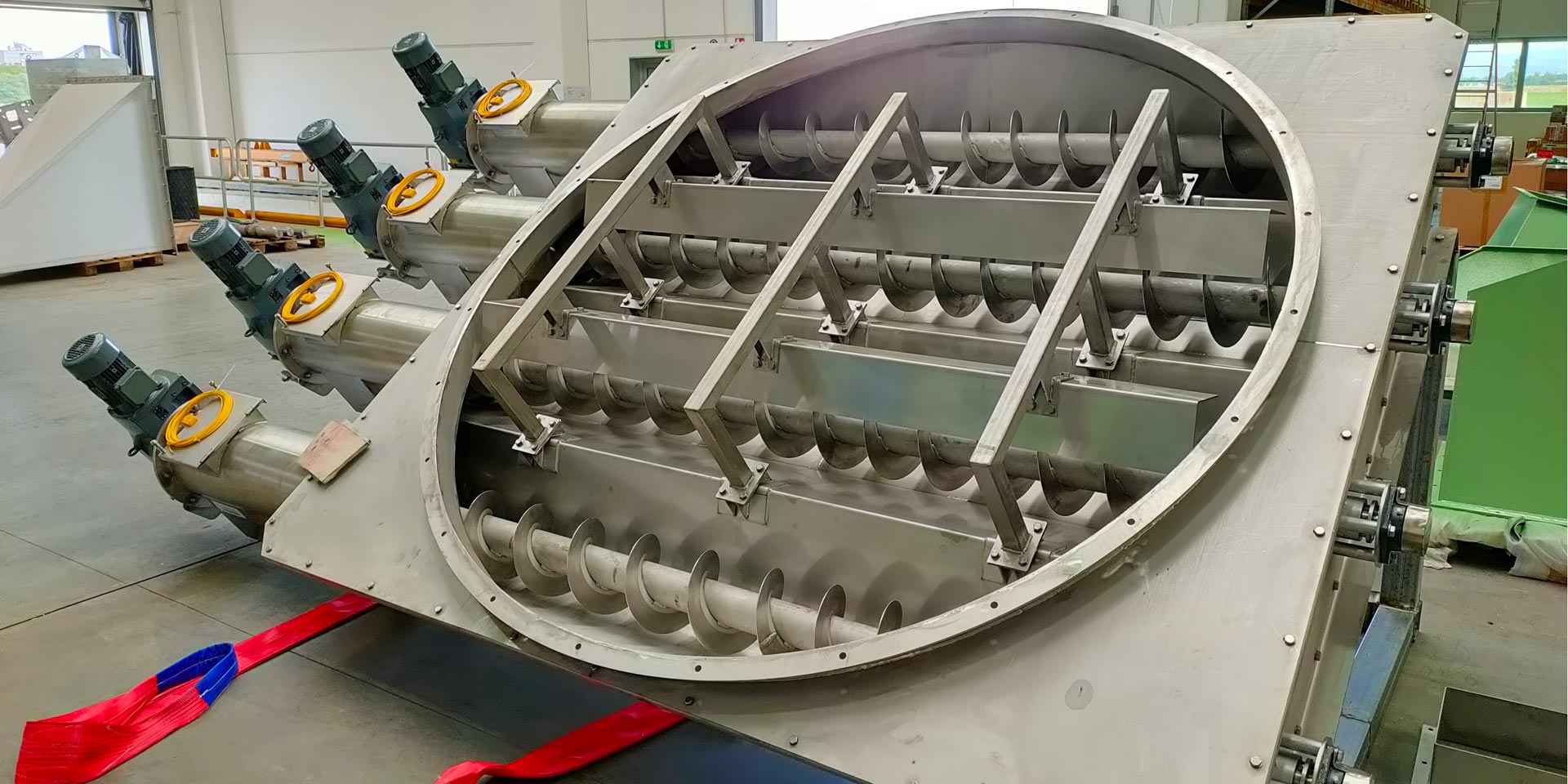

In many situations the bottom of silos and hoppers are required to be equipped with a multi-screw extraction feeder. This application allows the extraction of a difficult product from the silo or the hopper, avoiding “bridge” problems.

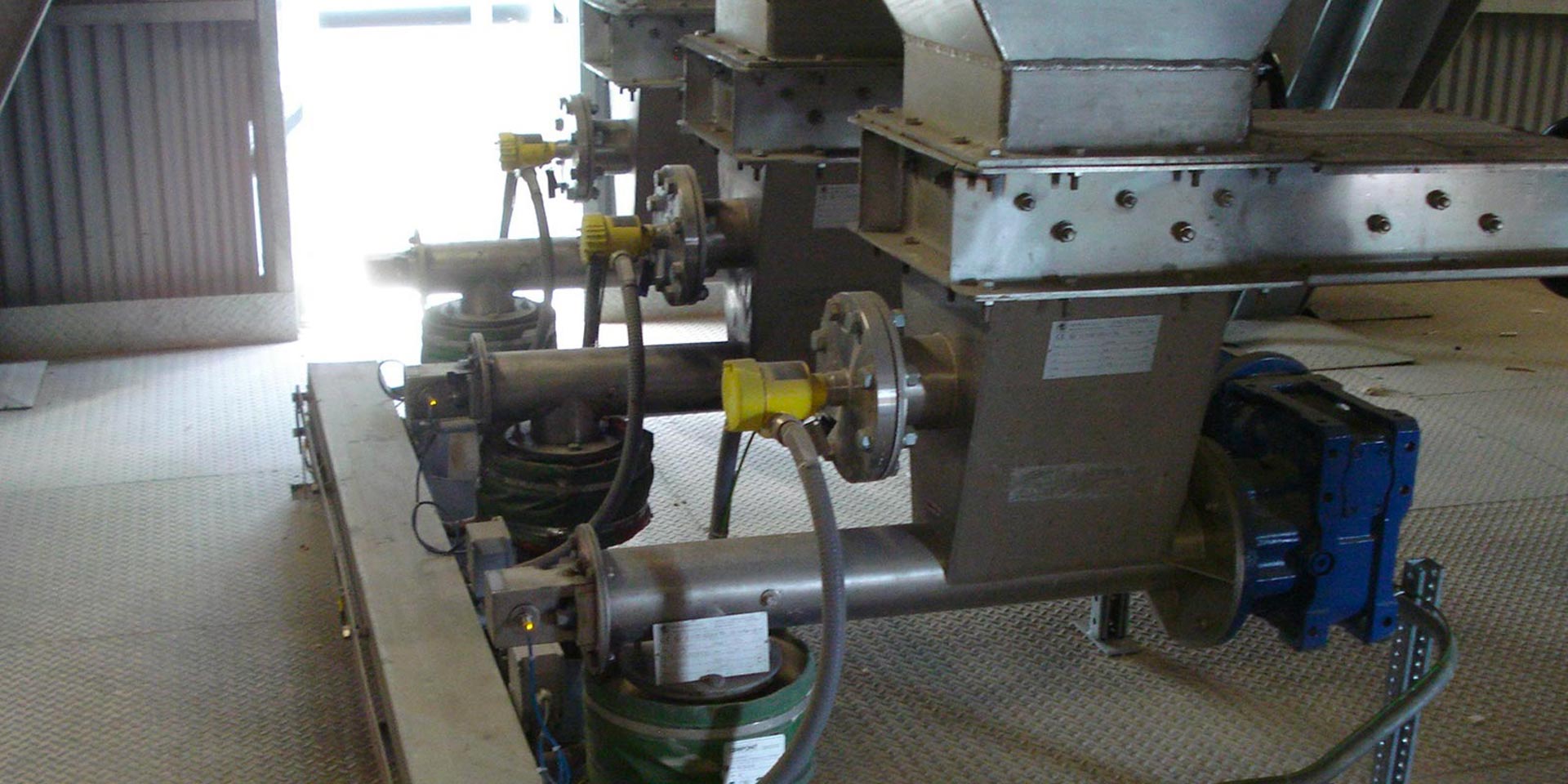

The inborn characteristics of the screw conveyors make them suitable for dosing products inside a process. Driven by means of variable frequency drive they can provide the right quantity of material at the desired ratio. Single or multiple screw version are available in Motridal range of production.

Download the Motridal brochure in PDF